Contact

General Inquiries

If you have any questions related to our products, the Koehler sales team will be happy to help. Just send us your inquiries using our contact form.

This e-mail service is intended exclusively for wholesalers, paper converters, printers, agencies, and graphic-design offices. We hope you will understand that we will not be able to respond to enquiries from private individuals.

Koehler Worldwide

For international product inquiries please contact our sales Partners.

Field of action 1

Living Many Lives

Loacker packaging wastepaper bales ready for the innovative recycling process.

From flexible packaging paper to elegant watch packaging: Loacker packaging goes through a long journey that is far from done when the last wafer is gone. Keep reading to learn more about how the packaging paper used by the confectionery company Loacker from South Tyrol is made in Kehl – and how it is given a new lease of life in the Thuringian town of Greiz.

FlexTech

Flexible packaging paper is suitable for packaging chocolate, tea bags, pet food, etc.

If the wastepaper bale that is currently moving along the conveyor belt at Koehler Paper’s Greiz mill could talk, it would have quite a bit to say. For starters, stories from old gossip magazines that were disposed of in the same wastepaper bin and were then pressed into a bale together with old love letters, shopping lists, math tests, and so on and so forth. But there is one tale that the wastepaper bale will always be able to tell: that of Loacker and its world-famous hazelnut wafers from Bolzano. With a recipe that was invented all the way back in 1925, they continue to delight the senses today – not just due to their flavor, but also due to the bright red packaging paper that is recycled here at the Greiz mill.

Loacker Wafers in Paper

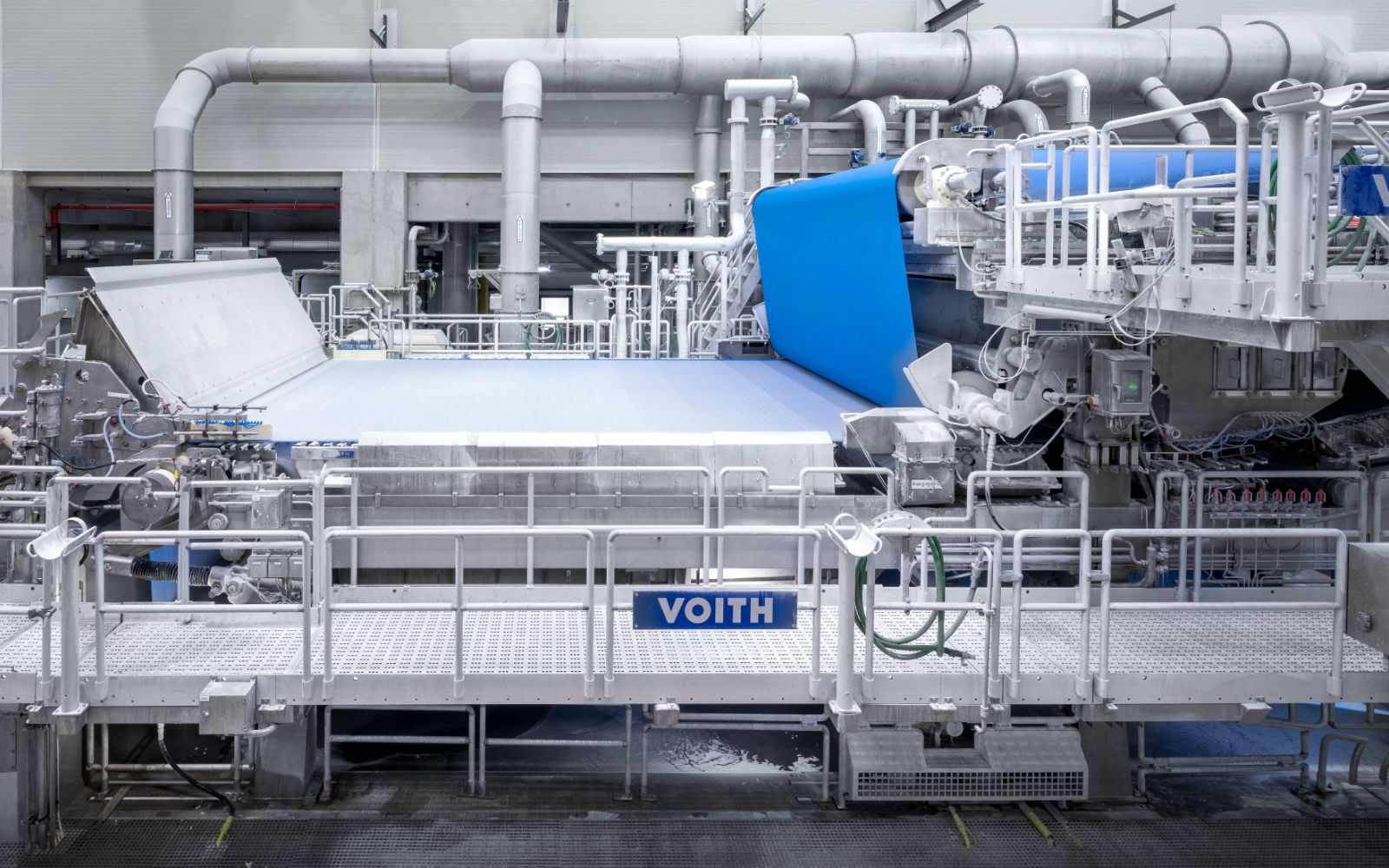

But let us rewind. After all, the journey taken by this wafer packaging started at a wholly different Koehler mill: Kehl. That is where the Koehler Group’s most cutting-edge paper machine was put into operation in 2019 for a new production line developed specifically for the production of flexible packaging paper – just like the one used by Loacker for its wafers. It starts with virgin fiber pulp that comes from certified sustainable forestry and controlled sources. The machine takes this pulp and turns it into up to 1,400 meters of packaging paper per minute that then gets processed further. And the energy required for this? Nearly all from renewable sources.

The advantage of using packaging paper? Easy: In comparison to plastic, it has a significantly better carbon footprint, since it can be recycled more frequently than pretty much any material out there. In fact, the quality of the recycled raw material is maintained even after several passes through the cycle. This is why Koehler made sure to develop flexible packaging paper with barrier properties that would be recyclable in standard wastepaper production processes and that would be able to replace plastic film in countless applications.

Up to

25

recycling cycles are possible before paper needs to be disposed of.

reeling

Discover the full journey made by Loacker packaging on our YouTube channel.

To the movie→From Kehl to San Marino

Loacker has not quite replaced all of its plastic packaging yet, but it is already using packaging made of Koehler NexPlus® Seal Pure MOB for some of its wafer varieties. However, before this paper can be turned into stand-up pouches for Napolitaner and other types of wafers, it must first travel from Kehl, through Italy, and to the SIT Group in San Marino. “Together with SIT, we were the first to offer a sustainable packaging paper option with excellent sealability and mineral oil barrier properties,” says Koehler Paper Italia Sales Manager Mauro Moretti.

And the impressive results were not lost on longtime SIT customer Loacker: “It really is a paper product with extraordinary properties. In fact, not only is it FSC®-certified, but also highly recyclable, as verified with the CEPI test method. Our experiences with it are proof: Koehler Paper provides truly premium products and has its finger on the pulse of the market, which has gotten an incredible response from our customers,” says Loacker Product Manager Gaia Ferrandi. And speaking of customers, they are the ones who get to see Loacker products packed in paper – at duty-free shops especially – before the packaging becomes wastepaper and is used as a secondary raw material.

“A variety of Loacker products have been packed in our paper for two years already.”

Mauro Moretti, Sales Manager at Koehler Paper Italia

Back to the Loop

The Loacker journey then makes a brief stop at a wastepaper sorting facility before moving on to a local recycled paper plant. In our particular story, that plant is Koehler Paper’s site in the Thuringian town of Greiz. And it is a site steeped in history, with paper production having begun here as early as 1591. Today, Greiz exclusively produces paper from secondary fiber raw materials. In other words: New paper is made from old notes, newspapers, wall calendars, posters, and, increasingly, flexible packaging paper. So it is, in a manner of speaking, the perfect place for Loacker packaging to be given a second chance at life.

During wastepaper processing, the Loacker packaging is processed into pulp together with other wastepaper. The highly developed dyeing technology used in Greiz makes it possible to produce recycled paper with a variety of colors that only few manufacturers can match. And the result can also be considered from a sustainability perspective: 80 – 90% of all the products made in Greiz bear the Blue Angel and EU ecolabels.

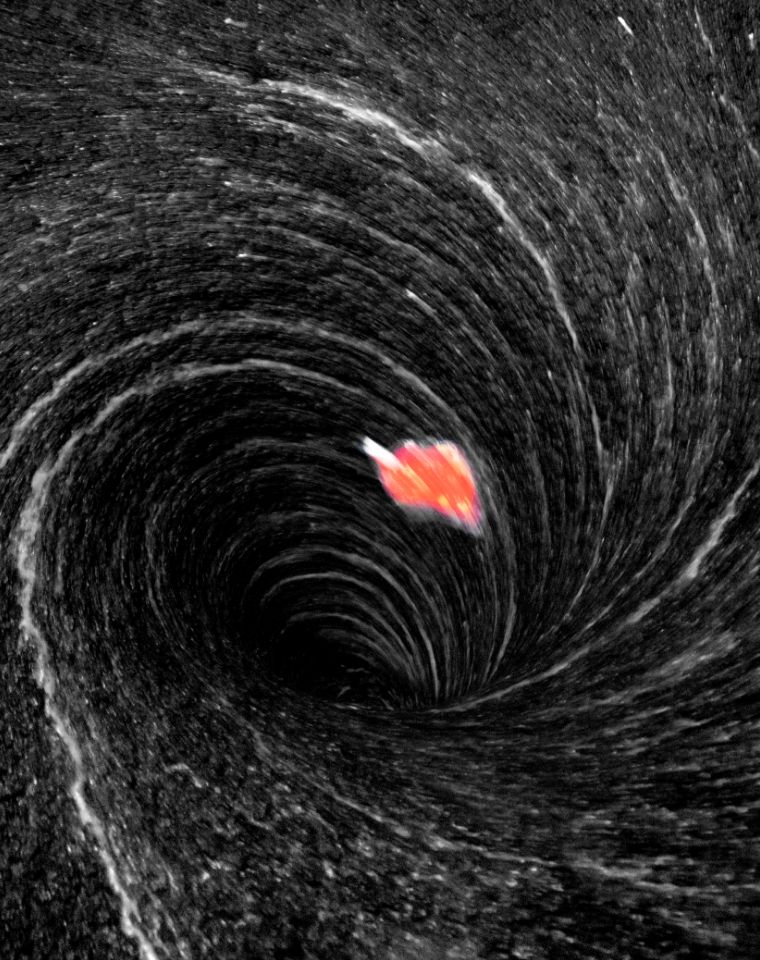

So what happens to the red wafer bag? It is turned into jet-black recycled paper in Greiz. This paper then makes a stop at a converter before continuing on its trip to luxury watch manufacturer Mühle-Glashütte in Saxony, where it is used as elegant packaging for watches. Recycling and exclusivity? They go hand in hand as far as Koehler is concerned. Welcome back to life, Loacker wafer packaging!

Naturally Circular

This is the loop that Loacker packaging follows in our story