Contact

General Inquiries

If you have any questions related to our products, the Koehler sales team will be happy to help. Just send us your inquiries using our contact form.

This e-mail service is intended exclusively for wholesalers, paper converters, printers, agencies, and graphic-design offices. We hope you will understand that we will not be able to respond to enquiries from private individuals.

Koehler Worldwide

For international product inquiries please contact our sales Partners.

Functional principle

HOW DOES THERMAL PRINTING WORK?

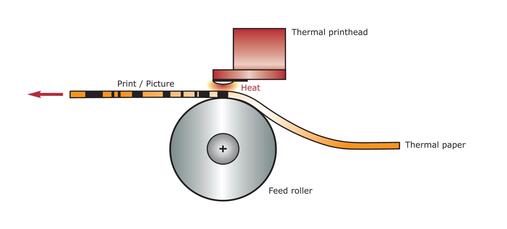

In the thermal printing process, the words or images are produced on the thermal paper by means of direct heat transmission.

This is done by the printer’s thermal head, which consists of numerous little heating elements. The heating elements are electronically controlled and produce thermal energy which activates a color reaction on the functional thermocoating. The numerous little dots this produces then go to make up letters, barcodes, and images.

Thermal printers have a relatively simple design and are easy to operate, which makes them considerably less susceptible to breakdowns. They are energy-saving, quiet, fast, small, and compact – and they require no other consumables, which in turn saves money and makes them highly reliable. They keep working even under extreme conditions.

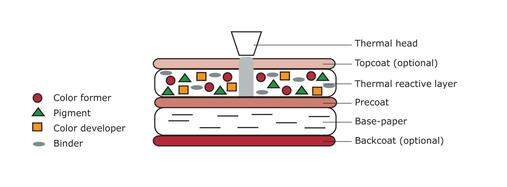

THE STRUCTURE OF CONVENTIONAL THERMAL PAPER

The thermal coating is then applied in the coating machine. It contains the principal functional components such as the color-forming substances and color developer. The thermal printer applies points of heat to the thermocoating, thus producing a chemical reaction that makes the lettering or image appear.

Thermal paper can also be given a protective coating on the front or back. A coating on the front (topcoat) is useful if the paper is to be exposed to mechanical wear, chemical influences, or environmental influences. A coating on the back (backcoat) provides additional protection when printing, laminating, and much more.