Contact

Press Contact

If you have any questions regarding Koehler Paper, the Koehler public relation team will be happy to help.

Just submit inquiry using our contact form.

NEWS #12

Koehler knowledge: Save on EPR Costs

Clear Competitive Advantage: Lower EPR Costs with Koehler NexPlus® Barrier Paper

With Koehler NexPlus® barrier papers, brand manufacturers can reduce EPR costs while packaging more sustainably. Discover how paper solutions can improve your total cost of ownership.

The packaging industry faces the challenge of meeting increasing requirements under Extended Producer Responsibility (EPR). We’ll show you how Koehler NexPlus® barrier papers enable you to package not only more sustainably but also more cost-effectively.

What Does EPR Mean?

EPR stands for Extended Producer Responsibility, an environmental policy approach that makes brands financially responsible for the entire lifecycle of their packaging. Manufacturers pay EPR fees based on the quantities of packaging or products they place on the market.

Brands are now confronted with new challenges in complying with legal requirements and related regulations. Rules vary across Europe and globally. In addition, EPR fees can differ depending on which waste streams consumers use to dispose of the packaging and the material composition of the packaging. In some cases, recycling certificates, reuse potential, or post-consumer recycled content may also play a role.

EPR fees can be allocated, for example, to investment in collection and sorting of packaging in each country.

Total Cost of Ownership – More Than Just Material Costs

Total Cost of Ownership (TCO) is a financial estimate designed to help determine the direct and indirect costs of a product or service. When switching from plastic to paper packaging, it’s important to consider not only material and processing costs but also indirect costs such as EPR fees. These are important to understanding the true advantage of paper packaging.

Practical Example: Comparing Oatmeal Packaging

We analyzed two scenarios for packaging with identical dimensions (300 mm x 265 mm) and 500 g of product content:

- Scenario 1: OPP film (Oriented Polypropylene), 73 gsm (80 micron). This grammage is commonly used for this type of oatmeal bag with 500 grams of content.

- Scenario 2: Koehler NexPlus® Seal Pure MOB, 72 gsm – CEPI-certified, recyclable, heat-sealable, with a mineral oil barrier. The barrier coating is a water-based dispersion coating with an application weight of 6 gsm. Dispersion coating is an established process in paper manufacturing.

To easily calculate EPR fees for packaging—based on material composition, recyclability, and country—the software Recyda was used.

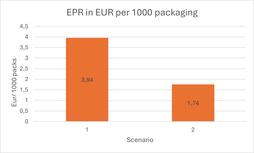

Below are the EPR costs per ton and per 1,000 packages, based on the average across 19 European countries*.

*Countries Compared: Austria, Belgium, Bulgaria, Czech Republic, Finland, France, Great Britain, Germany, Greece, Hungary, Italy, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Spain, Sweden.

Result:

With Koehler NexPlus®, EPR costs decrease by an average of 56% across 19 European countries—that’s €375 less per ton or €2.20 less per 1,000 packages.

In some countries, the savings are even more significant:

- Spain: 83% lower EPR costs (€6 per 1,000 packages)

- Belgium: 92% lower EPR costs (€10 per 1,000 packages)

Your Advantage: Sustainability and Cost Savings

With Koehler NexPlus® barrier paper, you not only meet recyclability requirements but also significantly reduce your EPR costs.

Interested?

Our expert team at Koehler will create a customized simulation tailored to your project and target countries. Schedule your appointment now and discover your competitive edge!